Consumer Demand Analysis and Suggestions on Ready-to-eat (RTE) and Ready-to-cook (RTC) Meals

Eva Chen(China Productivity Center Innovative Marketing Department)

I. Introduction

Taiwan's vigorously developing food industry has developed into a diverse array of styles, based on the rich traditional culinary culture, and on the strong R&D capabilities of the business operators. The busy life of modern people and the common habit of eating out have led to the emergence of the market demand for food items that are easily prepared but at the same time are nutritious and delicious. The 2015 Yearbook of Food Industry in Taiwan shows that there are about 6,000 food factories with 125,000 employees. The total output value in 2014 is NT$654.2 billion, ranking the 8th among the manufacturing industries. The industries that have growth rates of output values higher than average and a scale over NT$25 billion include those of manufacturers of prepared meals and dishes and manufacturers of bakery and steamed food products. The food industry is expected to grow by 13.3% by 2019. An Euromonitor study predicts the global prepared food market will continue to expand from US$91.7 billion in 2014 to US$110.9 billion in 2019 (Food Industry Research and Development Institute, 2015).

Even with the gloomy prospect of the global economy, "eating" is always an essential part of people’s livelihood. Ready-to-eat (RTE) and ready-to-cook (RTC) meals, which are easy to obtain and can be easily handled in a short time, have helped solve the dining problems of many people. There is, however, the concern of the processed food products losing the flavor of the original food ingredients. The food safety crisis that broke out in Taiwan last year had a huge impact on the food industry as many consumers have lost their confidence in the local food products. It is now an urgent need to regain the trust of the consumers, to present safe and delicious food, to really meet the needs of the consumers, and to have the food to contribute more to the health. It means that the development of RTE and RTC meal products needs to appeal to the demand for time saving, convenience, deliciousness, and health as the guidelines for research and development.

II. The concept and classification of RTE and RTC meal products

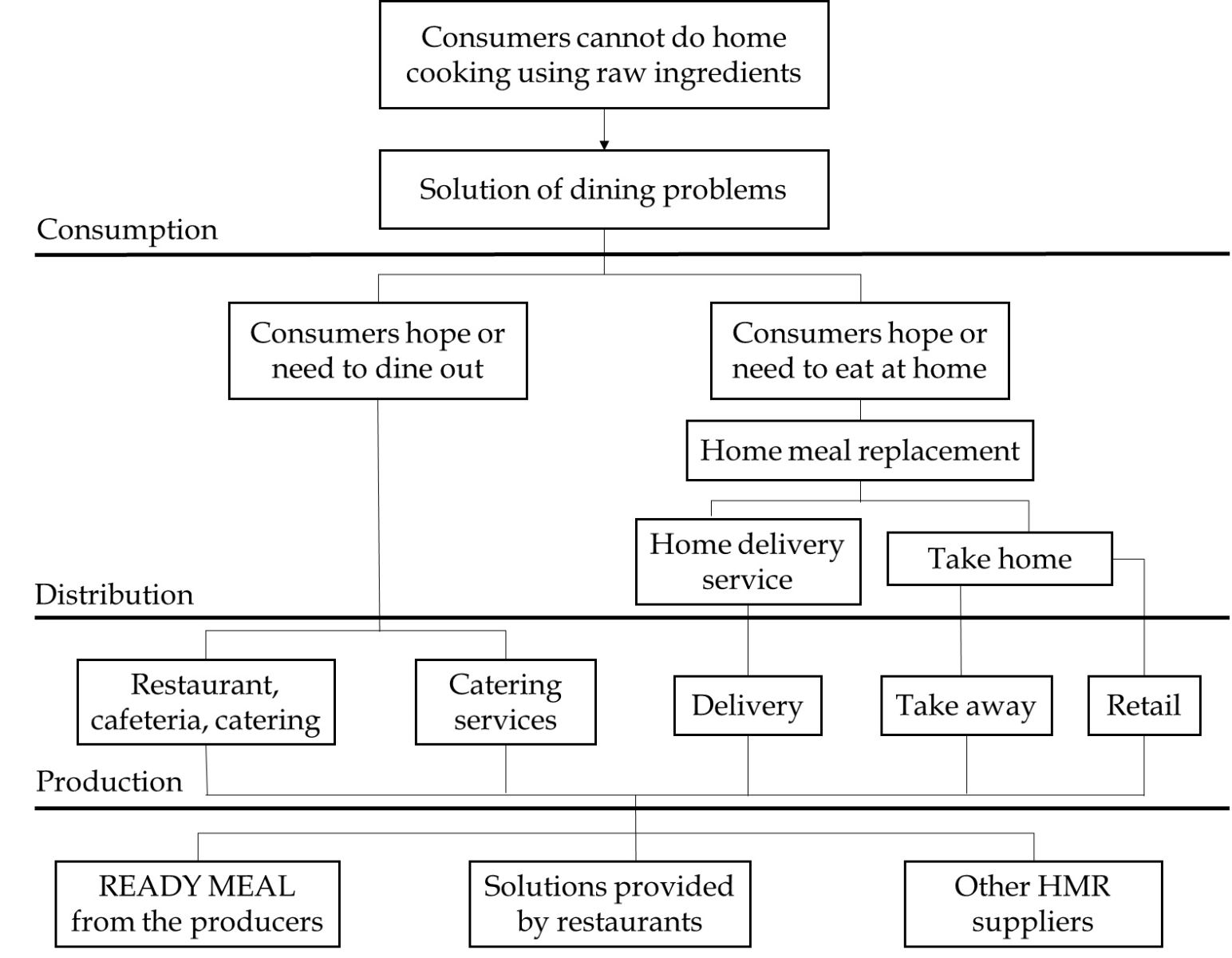

RTE and RTC meal products are generally known as prepared meals, which are also referred to as Home Meal Replacement (HMR), indicating the consumers’ preference or need of dining at home. The classification in terms of consumers is shown in Figure 1. The classification in terms of heating and cooking methods is shown in Table 1. The idea of HMR originated in the US to provide consumers with meals of the same quality as served in restaurants. At that time, shortened dining time, higher employed female population, and increased opportunities for dining-out gatherings all contributed to the fast-growing food market. In Japan, HMR is defined as "intermediate meal", a meal between dining out and family meal. It can be consumed with the least amount of preparation or even no preparation at all but preserves the good tastes produced by experienced restaurant chefs. Consumers now require the least amount of food processing time, so this is a prominent demand on HMR products. The diverse types of the HMR foods also make standardization highly difficult. The biggest challenge is to introduce innovative business models in the food supply chain. It would take the power of the IT system to refine the supply chain and restructure the value chain in order to enhance competitiveness (Fu Chen-Jui and Min Ting-Hsiang, 2008).

Data source: A.I.A Costa,M. Dekker ,R.R. Beumer,F. M. Rombouts & W.M.F. Jongen (2001), quoted from Hsu Yun-Shu (2007)

| Types | Abbreviation | Concept | Main food items |

| Ready-to-eat meals | RTE | Prepared and ready for immediate consumption | Fried Chicken, ham, cheese, roast beef, salmon, sandwiches, soups and other hot foods. |

| Ready-to-heat meals | RTH | Prepared and ready for consumption after a short period of heating | Heated fish or meat, boxed dish ingredients. |

| Ready-to-cook meals | RTC | Not prepared but are ready for immediate preparation | Boxed meats, unfrozen raw pizza, raw pasta |

| Specialty-Perishables | SP | fresh ready-to-eat food | Fruits, Cut Vegetables (Boxed) |

Data source: Hsu Yun-Shu (2007)

With the wide variety of foods today, HMR, in a broad sense, no longer makes a clear distinction between meals and snacks. Items that used to be classified as breakfast, such as sandwiches and rice balls can now be treated as breakfast, snack, lunch, or dinner when sold in convenience stores. Consumers in Taiwan can easily buy ready-to-eat meals and have their meals and snacks all at convenience stores. Hot or cold food, Chinese or Western style, fresh food at 18˚C, fresh food at 4˚C, bread at room temperature, etc. can be obtained at self-service kiosks, where diversified services are readily available. The creativity exercised by the businesses, combined with new production technologies and more rich-flavored cuisine combinations can meet consumers' expectations and have unlimited potential.

III. Observation on consumer demands for RTE and RTC products

The changing consumption patterns in modern society are a main reason for continued growth of the food industry. The main features noticed include the following:

Declined birth rate: Modern families have fewer and fewer children. Most families have just one or two children. Schools have problems recruiting students. Most families used to go shopping for a whole week’s food supply in a supermarket. Small families now are reluctant to stock large packs of food items, which can hardly be finished before the expiry date. Small and exquisite packaging is more practical. And now in most families both parents need to work so they are too tired to prepare a full dinner after working a long day. Usually, they would choose to eat out or make something at home for a simple dinner. This phenomenon has raised the demand for food products of diverse types but small in size.

Aging society: The Council for Economic Planning and Development of the Executive Yuan (2010) estimated that the number of elderly people will increase so that the proportion of the 65+ years old population in the whole population will increase from 10.7% in 2010 to 41.6% in 2060; and the proportion of the 80+ years old population in the aged population will increase from 24.4% in 2010 to 44.0% in 2060. Taiwan is quickly turning into a super-aged society. The food for the elderly needs special preparation, mainly soft in texture and containing nutritional supplements. The outer packaging would need careful design to be easy to handle. The market of the elderly consumers requires special research and development for emerging business opportunities like home delivery.

Single economy: High urbanization and delayed marriage have become a trend, and there are even many people who simply reject marriage. Online business platforms on mainland China have invented a Bachelors’ Day on November 11, making it an "online shopping carnival". There are hundreds of millions of orders pouring in on that single day. Some restaurants have designed single customer seating areas, one-person-size hot pot dishes, and even instant food packaged in single portion. These are all for the business opportunities for single customers.

Health care: Food safety issues are a main concern for many people now. Consumers are advised to eat "food" rather than "food products", as the latter usually contains harmful additives for better tastes and longer storage periods. There is an irreversible trend towards organic and health foods. Fruit boxes and bananas in plain packaging are easily found in supermarkets, as well as juice and fruit drinks. Some products appeal to customers with the use of less sugar and less oil. Certain drinks sell especially well with the appeal to the use of biotechnology in production. The use of dietary fibers and camellia extract, etc. makes the food healthy with low calories. Light meals with vegetables and fruit are mostly targeted at female consumers. The freshness, nutrition, good taste, and healthiness are the key to winning the market.

(5) Vegetarian orientation: More and more people now go vegetarian, for religious or health reasons. Generally speaking, fruit and vegetables are good for health. Many vegetarian or lacto-ovo vegetarian developed with clear labeling and traceability information, so the consumers clearly understand exactly what they are eating. The fruit boxes and semi-processed vegetables in supermarkets save consumers the time of cleaning, peeling, and adding ingredients. Consumers now are more concerned of the source of the materials and the quality of the cleaning and freshness-retention technologies.

(6) Climate change: In frequent weather anomalies, more rainy days means fewer occasions for dining out. People often store frozen food or prepared food at home to make simple and delicious meals. Diverse types of frozen prepared food that can be easily reheated and still maintain the freshness and delicious taste can boost sales of associated products such as refrigerators and kitchen appliances. Factors like the retention of freshness and the right temperature, the sizes of servings and packaging all need to be taken into account in operation.

Environmental protection: With the rising environmental consciousness, measures of reducing transportation for import and increasing the use of local ingredients are implemented to reduce the carbon footprint. Some enterprises release organic food products with carbon label certification to display a green and innovative supply chain and marketing model. By highlighting the local features of the products, the friendliness to the environment, and the green packaging design, the trust of consumers as a whole will be enhanced. For instance, the onsen tamago (hot spring eggs) produced by Shih-An Farm (16 individually wrapped eggs in one pack) have clear labeling of the carbon footprint ratio of each stage in the product life cycle. And to compensate the relatively high carbon footprint ratio in the raw material acquisition stage, chicken manure is used for biogas power generation. This is the commitment to the ideal of carbon emission reduction.

Increasing costs of operation: Considering the increased rental cost, some restaurants no longer provide eat-in services and encourage take-away meals with certain discounts, as a way to save the costs of space rental and service personnel. The costs on the salary of the service industry are increasing along with the higher costs of labor and health insurance and the lack of workforce all indicate the necessity for changes and adjustment of the work process. For instance, the smaller kitchen requires the prior processing of the ingredients into semi-finished products transported to the store, which can be offered for sale only after heating or assembling. RTE and RTC operators provide semi-finished products to simplify the work processes.

IV. Advice for business operation

As mentioned above, the RTE and RTC markets will be blooming. For B2B, B2C, or O2O supply operators, when referring to future consumer demand trends, development and innovation can be proceeded with reference to their own products or services for preparation of all business opportunities. The following are some suggestions we would like to give to the operators when they are faced with related problems and challenges:

1. Value the freshness-retention and packaging technologies for the establishment of a cold chain logistics system

RTE and RTC foods on the market are roughly divided into two categories: room temperature and refrigerated. Temperature plays a key role in the storage of foods of different natures. At each stage of the process, i.e. the completion of production, distribution, in-store sales, and consumption by consumers, the temperature is a key element. Spoiled food in the process will be nothing but a waste and a loss. For both the room-temperature and the low-temperature food items, packaging considerations include the extended shelf life, safe and hygienic quality, and resilience during long transportation to ensure the high-quality and consistent products. Nowadays, with the technologies of rapid freezing, packaging, thawing and reheating, and low-temperature circulation, the problems of spoiled frozen foods have been reduced to the minimum and even no preservatives have to be used. At present, freezing technologies have a wide range of applications, including ready-to-eat products that cannot endure high-temperature sterilization or do not require reheating, such as dehydrated fruits, canned fish without added preservatives, pickles, caviar, dried persimmons, and other prepared foods. Advanced preservation technologies can adjust the seasonal problems of perishable aquatic and agricultural products, to minimize wastes, reducing price fluctuations, extending the sales time, and stabilizing the income of the retailers.

Cold chain logistics is the best assistance to the food industry in providing products and services. Usually cooperation is established with professional cold chain logistics companies to ensure the products reach the consumers in a hygienic and safe manner with the lowest amount of investment of logistics system establishment. Cold chain logistics refers to the technology that ensures that food can be kept at a certain low temperature during the process of production, storage, transportation, and marketing ant that ensures food quality and reduces loss. The technological requirements are more demanding than those of the normal temperature logistics systems and the technical management more complex. Taiwan's current cold chain logistics technology has fully utilized the application of smart logistics and logistical research. In addition to the functions of transportation and storage, it also involves technical services such as multi-layer distribution and logistics traceability, providing added value of consumer behavior analysis and management of sales performance at various sales sites (DIGITIMES Business Newsletter, 2015).

Laurel Co. Ltd., a leading brand of RTE and RTC in Taiwan, started its business from hot pot ingredients and later expanded to frozen prepared foods, such as hot pot dumplings, glutinous rice balls, mayonnaise, scallion pancakes, fried rice, and pasta. There deserve to be called the pioneer developer of automatic production of hot pot dumplings. Recently, they have carried out vertical integration and invested NT$1 billion to build a low-temperature logistics center in compliance with international standards. The purpose is to integrate the talent and technologies on low-temperature logistics to be closer to the needs of customers in an efficient supply chain, with full control of the quality. Laurel is well aware that distribution is an extremely important link in cold chain logistics. In the process for perishable items transported from the producer to the end consumers, more than 80% of the time is spent on distribution and transportation. Therefore, it is of great significance to design the distribution process so the distributors can reasonably arrange vehicle scheduling to shorten the time on the way, thereby reducing logistics costs and damage costs, and ensuring the food safety of the end customers.

2. Establish a central kitchen, introduce automation equipment, and solve manpower problems

RTE and RTC food manufacturers in Taiwan are mainly small and medium-sized enterprises. They have the concept of a central kitchen, but lack a comprehensive understanding of their actual practices. A central kitchen is not equal to a kitchen large in size. The purpose of establishing a central kitchen is to maintain stable and consistent quality during the mass production process, and to reduce procurement costs through unified procurement. The focus of planning is on the smoothness of the food processing process, and it is based on food safety, including mechanical space, personnel operation space, trolley operation space, future equipment expansion issues, compliance with food safety regulations, etc. It is necessary to standardize and simplify the operation process design for overall arrangement. If the process is properly arranged, the heavy lifting job can be done by the machines, so even female workers can operate with a minimum period of training. This means more competitive advantage in the development of online shopping and chain businesses. The central kitchen combines automation equipment and smart cloud technology applications to improve production efficiency. Operators only need to do key management, and technological control reduces errors, which will greatly reduce on-site service manpower.

Formosa Chang is a most popular brand name for the classic braised pork rice in Taiwan. It has formed a strong chain enterprise with decades of effort starting from just a roadside stall. To ensure the quality of its many products and to maintain the consistent flavor, a central kitchen is used with advanced equipment. Through the food design and vacuum packaging, the original flavor of the products is maintained so that consumers can enjoy the delicious meal after simple reheating. Formosa Chang also cooperates with supermarkets to sell ready-to-eat meals such as minced pork rice and chicken rice as well as exquisite gift boxes. The convenient packaging is developed for take-out items to enlarge the consumer group beyond just eat-in customers. The central kitchen and the automation equipment help integrate the physical and virtual marketing channels to achieve better performance in terms of product popularity and revenue.

3. Business Service 4.0 and technological management thinking

The food industry is facing the process of industrial upgrading and transformation driven by technology, intelligence, and mobility. The revolution brought about by the entire supply chain includes the changes in all the channels derived from the Internet of Things. The application of technologies has also promoted innovative services that will greatly affect the future business development models of the entire food industry. For instance, the food safety traceability system using the QR Code on the product packaging allows the consumers to scan the code and obtain all the production information. Accurate analysis of future sales items and quantities is possible through integrated Big Data applications. Traditional marketing models have been subverted. Business service 4.0 represents the use of information, e-commerce, real-virtual integration, and smart life. The services provided will be ubiquitous, especially in terms of the development of mobile commerce, individual needs and customization service.

Tanhou Food, a food enterprise in strategic alliance with Family Mart, is founded by Mr. Liu Tan-Hou, who is known as a technological legend in the food industry. The scope of production encompasses fish, pork, poultry, and vegetables. Consumers can use the app to check the traceability information of the production, the SGS inspection reports, nutritional content, and even recipes. With the use of technologies, the business philosophy of sharing with others is realized to have related supermarkets, online shopping channels, bakeries and the HD Foods eateries established, signifying the integrated services through powerful technological management. The HD Foods eateries of Tanhou runs on an interactive information model, using the augmented reality (AR Code) technology. Consumers just download the APP on their mobile phones and choose the items on the menu for purchase. Detailed information of all the main ingredients on the menu is also displayed, such as data streaming, discount promotions, giveaway activities, etc. Consumers enjoy an interesting experience and feel assured of the quality of the ingredients. And footprints of the purchase made are also recorded among the big data and sent back to the management system of the business.